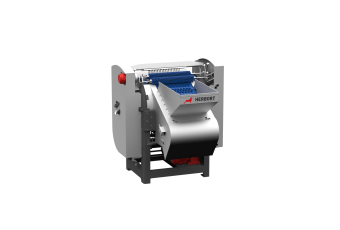

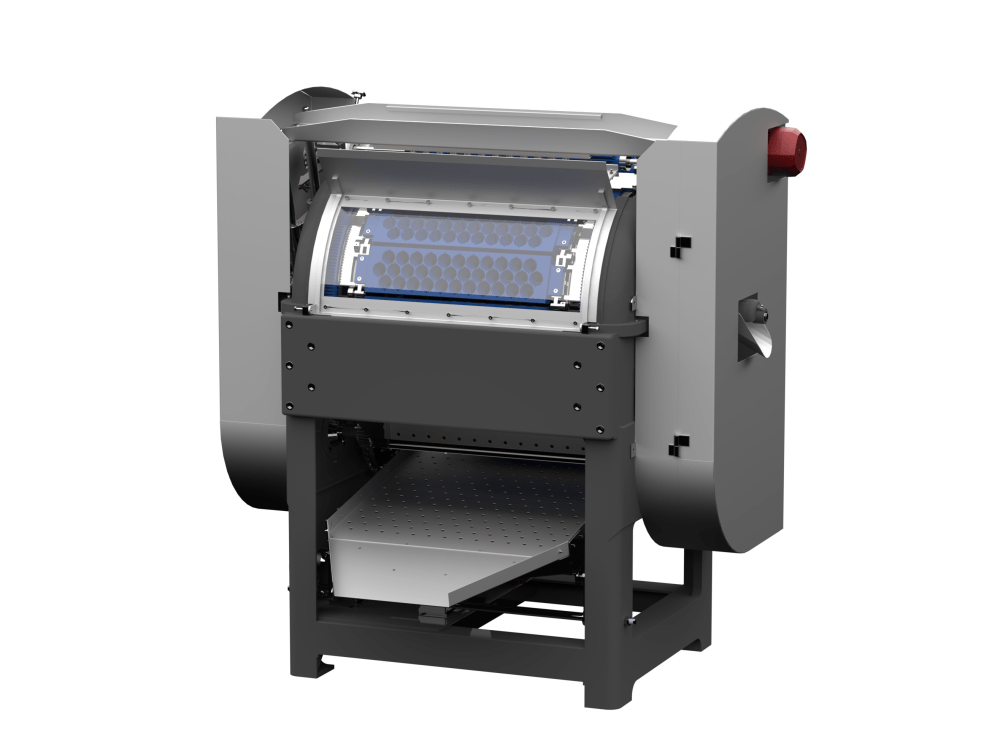

Pit remover 27

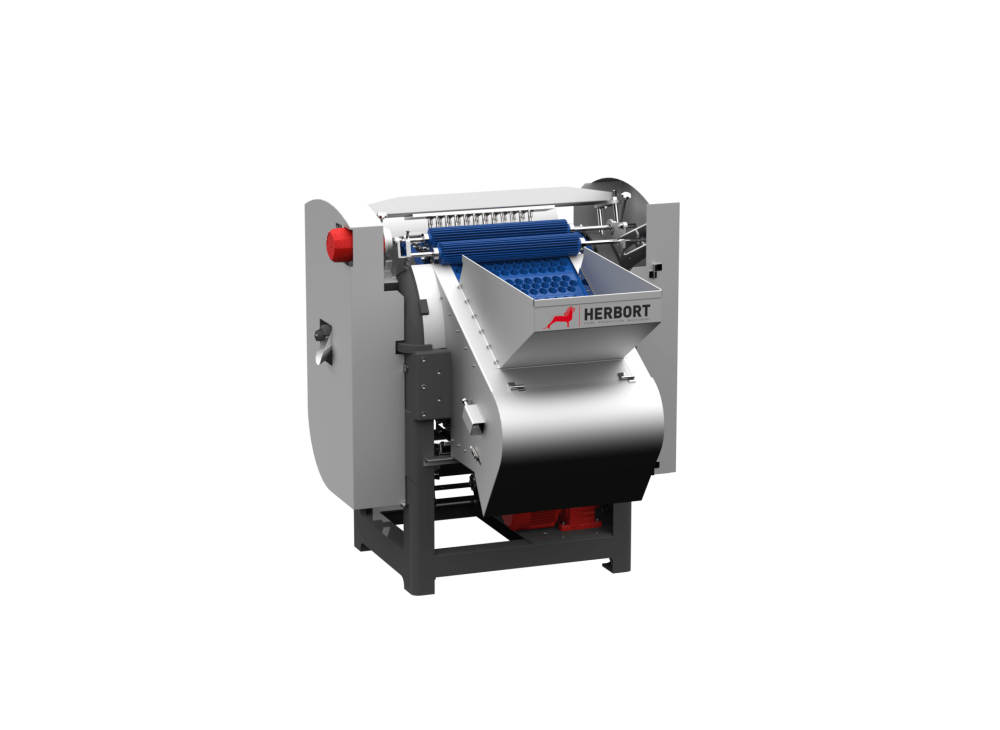

This pit remover 27 is best suited for removing pits and stones from fruit such as sweet and sour cherries, yellow plums, greengages, plums, apri-cots, etc. The machine is fitted with a pitting drum to process small products.

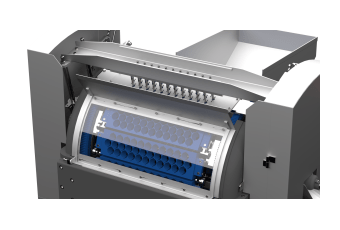

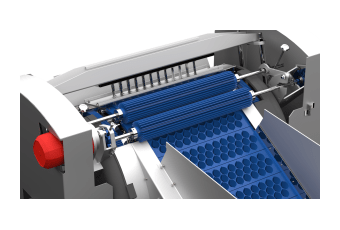

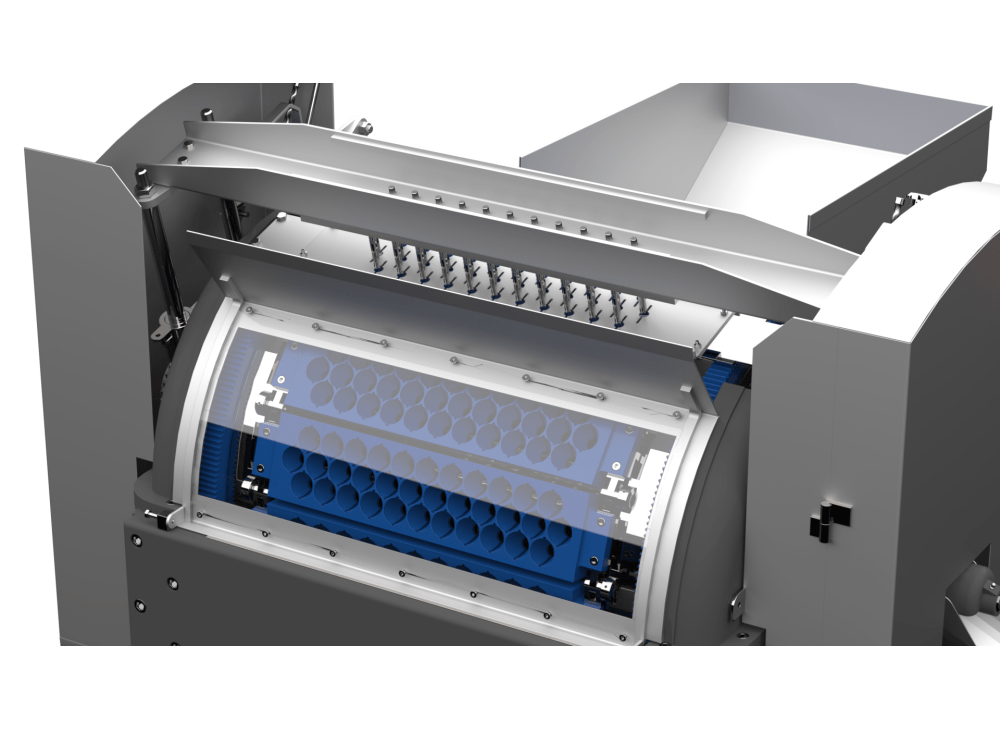

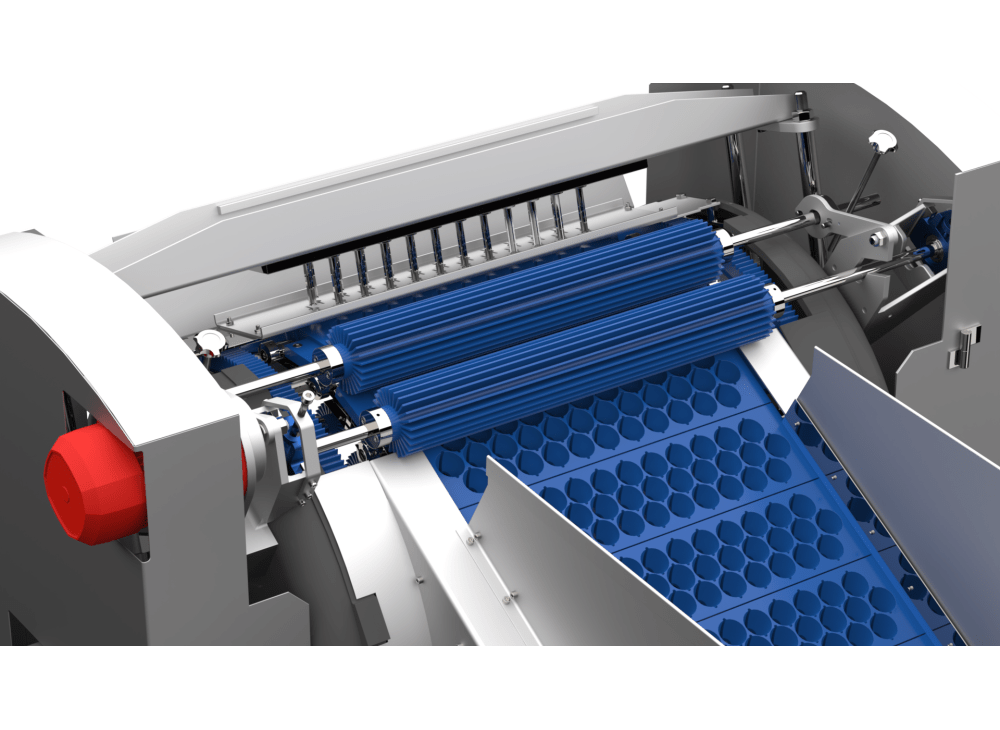

The product is fed into the machine’s hopper and is sorted through the pan holes of the rotating drum. Surplus product is retained by a round brush which is driven. The rotating drum trans-ports the product to the plunger area. The plungers are inserted into the prod-uct from above and push the stone out of the fruit. Whilst the stones are being re-moved, the fruit is supported by the rub-ber slides. These rubbers separate the stones from the product at the same time. The stones fall into a spiral trough located in the centre of the drum and are transported by the spiral trough to the side and out of the machine.

The pitted fruit falls onto a vibrat-ing tray located underneath the drum and is transported out of the machine. Stuck fruit is pushed out of the pitting pans by the ejectors which are located in the centre of the drum. The vibrating device has round holes; small matter is separated from the fruit and screened separately.

To process plums and apricots, the machine is fitted with a slat conveyor. The plungers are fitted with blades; the fruit is halved during the pitting process. The continuous operation and high insertion speed of the plungers ensure that a high percentage of stones are removed and that the pitted fruit retains an excellent appearance.

Technical data

| Machine 27 | with drum | with conveyor |

| Capacity | 1600 – 2400 kg/h | 1500 – 2200 kg/h |

| Product diameter | 18,0 – 30,0 mm | 31,0 – 47,0 mm |

| Number of plungers, depending on fruit size | 74 – 117 | 22 – 42 |

| Length | 1640 mm | 1640 mm |

| Width | 1580 mm | 1580 mm |

| Height | 1700 mm | 1700 mm |

| Power | 1,5 kW | 1,87 kW |

| Net. Weight | 1250 kg | 1400 kg |