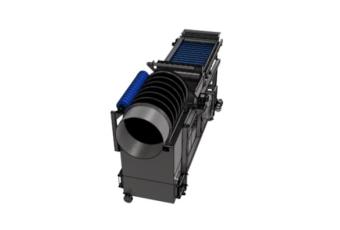

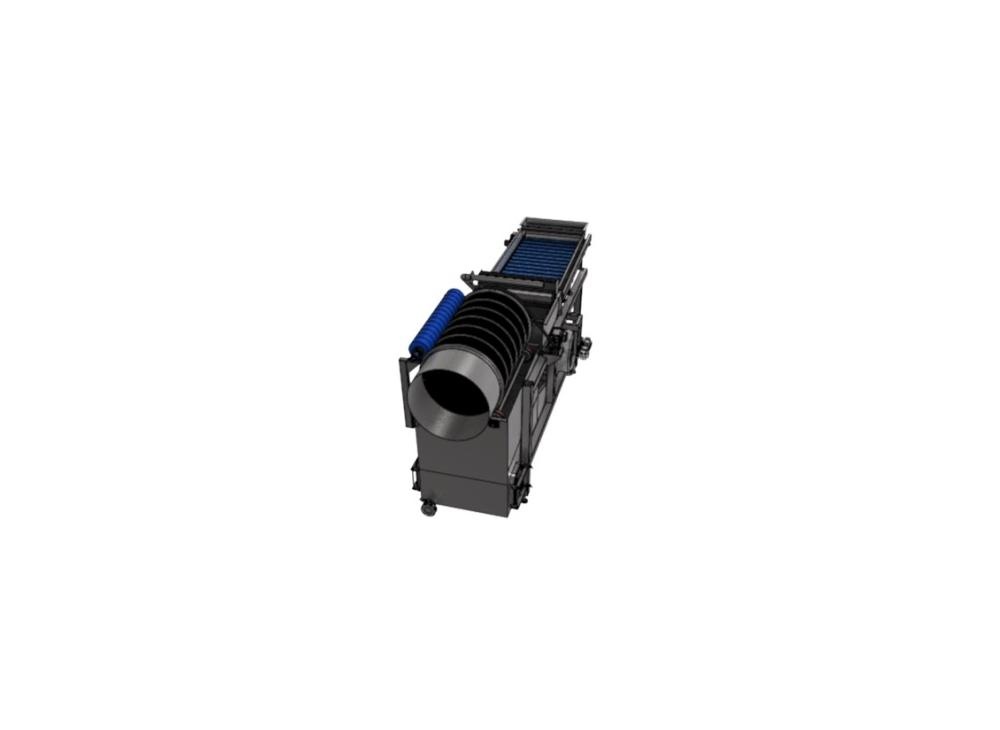

Flotation washer

This flotation washer has been developed for the washing of peas and other, similar products. The product is washed extensively so that stone, dirt, leaves, pods parts and whole pods are removed. The peas are washed in a water stream. The products arrive in a container where water enters from below. The products arrive in the raid container, where water from the bottom inflow. The product is spread over the full width of the flotation washer and then fed to the stone trap.

The peas are carried with the water flow over the conveyor belt. Heavier components such as stones are held back by the transverse-positioned tread blocks, which were mounted onto the conveyor belt. The conveyor belt, which periodically turns against the stream, deposits the secluded elements into a flume. This flume carries the elements to the drum. The water which is necessary for transport flows in the drum and ends up in the water-collector, at the bottom of the machine. From here the water is pumped back into the cycle. The amount of water is regulated by a pressure valve, which is mounted on the side.

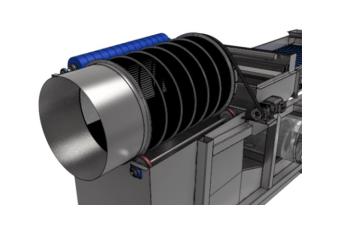

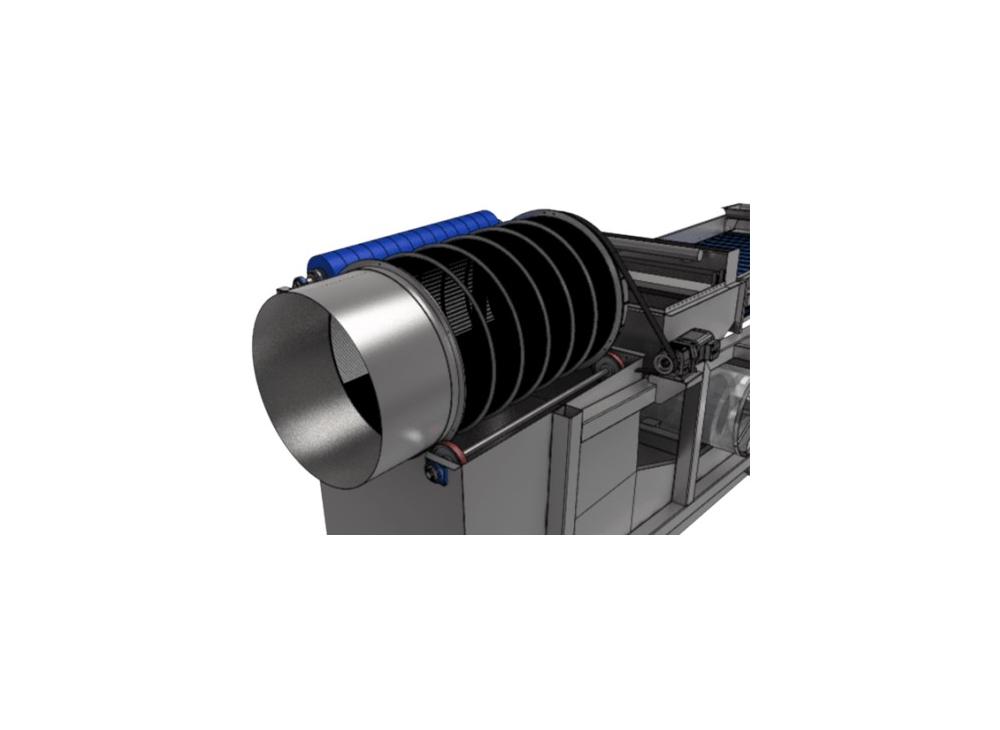

The peas and light dirt arrive in a settling tank. The lighter elements are flushed over the wall at the end of the tank and are carried away with the overflow water from the washing drum. The washing drum is working on a constant speed. The dirt particles are separated, the water passes through the drum to the draining platform.

The peas settle in the settling tank. By means of two pipes, they are fed to the washing drum, where they are cleaned. The drum is perforated with slits of 20 x 2 mm.

Technical data

| Capacity | 10000 kg/u |

| Power | 9,35 kW |

| Water usage | 3,0 m³/u |

| Length | 6140 mm |

| Width | 2315 mm |

| Height | 2650 mm |

| Weight | 960 kg |

Special features

- Fast, thorough cleaning of peas

- Easy to maintain and clean

- The flotation washer is made from stainless steel, with exception of the bearings and power unit

- Low water usage

- High capacity

- With continuous water cleaning unit